Innovative use of recycled crushed glass as sand replacement in structural concrete – Tunnels & Stations, Metro Tunnel Project – Environmental Outcomes

CYP Design & Construction (CYP D&C) is supporting an innovative research study including field trials using recycled crushed glass from kerbside waste as a sand replacement in structural concrete.

CYP D&C – a consortium consisting of John Holland Pty Ltd, Lend Lease Melbourne Metro Pty Ltd and Bouygues Construction Australia Pty Ltd – is designing and constructing the ‘Tunnels and Stations’ delivery package of the Metro Tunnel Project (Melbourne). The Project is the largest public transport infrastructure project in Victoria’s history. With 750,000m3 of concrete required to deliver the Tunnels & Stations, CYP D&C identified a significant opportunity to reduce embodied carbon emissions that would require a multifaceted approach to shift away from a business-as-usual way of building concrete-framed infrastructure.

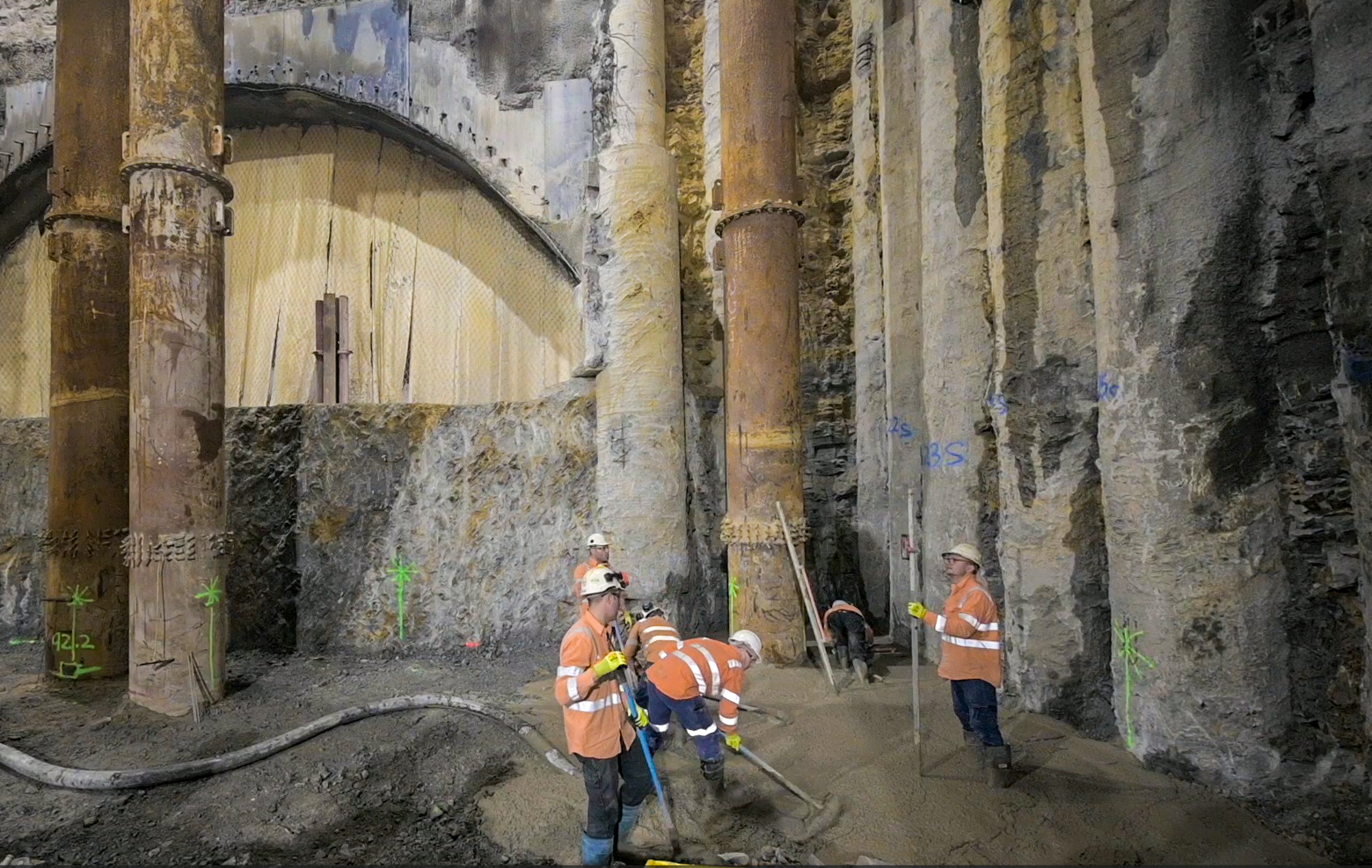

In collaboration with the University of Melbourne, Holcim Australia and Vortex Industrial Solutions, CYP D&C has worked to prepare concrete mix designs that incorporate vortex-processed recycled glass as sand replacement. From July to December 2022, CYP D&C trialled a concrete mix with 25% recycled crushed glass as sand replacement in blinding mixes on suspended slabs at the La Trobe site for the construction of the new State Library Station. As part of the trials, 235m3 of concrete containing vortex ‘glass sand’ was poured.

The trial aimed to investigate the material and structural properties of the glass sand concrete mixes. It investigated how processing the crushed glass through the unique vortex technology affects its surface chemistry, particle size and shape, and how to utilise recycled glass in structural concrete mixes instead of conventional or virgin sand.

This innovative project ultimately aims to conduct important experiments to bring glass-based concrete materials to industrial scale production and use. The key objectives of the project included:

- Undertaking durability tests and relevant compliance checks against regulatory standards;

- Undertaking structural compliance tests; and

- Determining the level of silicosis in the dust when the glass-based concrete elements are excavated.

The trials were successful due to significant partnerships and collaboration between CYP D&C, research institutions and industry. Discussions with the University of Melbourne began in 2020 as part of a Research Framework between CYP D&C, University of Melbourne and RMIT University, with a focus on recycling or upcycling industrial by-products into concrete.

Vortex Industrial Solutions operates a pilot vortex processing plant in Melbourne, allowing select institutions to use the plant to further investigate unique product management methods and materials development. Vortex Industrial solutions was engaged early to supply vortex-processed glass sand for the research and testing, and later for the project trials using crushed kerbside waste glass supplied by Cleanaway.

As CYP D&C’s primary concrete supplier, Holcim Australia was engaged to supply glass sand concrete batches for the temporary blinding trials, and supported research by undertaking ‘hot box’ tests immediately following batching. The hot box test was used to predict the insitu concrete temperature during the concrete pour.

As a result, CYP D&C and the University of Melbourne have worked closely with industry collaborators to implement the innovative approach to turn glass waste into a value-add product.

What were the OUTCOMES and how were those outcomes shared?

The research study and trials undertaken have proven the suitability of using waste-based glass sand in structural concrete (as opposed to non-structural concrete), and delivers an innovative recycled content solution that reduces virgin material use.

To the best of our knowledge, recycled glass has not been used as a sand replacement in structural concrete for any building or infrastructure projects in Australia, if not the world. Its use has primarily been limited to low grade non-structural applications such as council footpaths and pavements.

The use of the glass waste as a partial sand replacement is generally considered to be noncompliant with existing guidelines from organisations such as VicRoads, including the VicRoads Section 610 standard required for all permanent works on the Metro Tunnel Project. This is due to the higher alkali content within the vortex glass sand concrete mixture. The alkali content of the glass fines can influence the potential for alkali-silica reaction (ASR), a chemical reaction that can cause significant expansion and trigger cracking in the concrete matrix.

However, this trial has found that using washed vortex-processed recycled glass in concrete reduces the ASR potential as it chemically interacts with cementitious products to form low-permeable phases. It also decreases the pathways for moisture ingress into the concrete matrix and results in a more durable product. Additionally, the field trials confirmed that the use of glass sand had no impact on pumpability or workability of the concrete, as was previously thought to be a possible complication with the product.

Based on the successful results obtained to date, CYP D&C is preparing a proposal to VicRoads to request dispensation for the alkali content noncompliance, based on the ability of the glass fines to reduce the ASR potential. VicRoads standards also currently limit fine aggregate replacement to 30%. This proposal aligns with recent calls for the greater use of performance-based specifications over prescriptive specifications, which promote the development and use of innovative and sustainable concrete technologies. CYP D&C is exploring further opportunities with the University of Melbourne to continue trials in permanent works, and pending further engagement with VicRoads, is also looking to increase the sand replacement from 25% up to 80% in future trials, once the durability performance of the mixes can likewise be proven.

Circular economy: reducing virgin material use

This trial proves the reliability of innovative circular economy solutions in structural concrete and reveals the exceptional achievements being made in this area of product development. At the same time, the trial has significantly reduced reliance on virgin sand – which is an unsustainable practice – by using a waste product that would otherwise be sent to landfill.

Sand from the desert is generally considered unsuitable for use in concrete, so virgin sand is sourced and transported from rivers, lakes, oceans and beaches, causing negative ecological impacts. Replacing virgin sand with recycled crushed glass reduces the need for additional sand mining. This trial is paving the way for innovation in circular economy, with a shift away from unsustainable linear economy principles of using virgin sand.

Knowledge sharing

Information was shared between all stakeholders at various milestones of the project trials, with all stakeholders working collaboratively but still respecting the Intellectual Property of the University of Melbourne’s research. CYP D&C and industry partners have provided in-kind-contributions to support the ongoing research and have supported the recent ‘Large Scale Production and Deployment of Concrete Containing Glass Waste’ funding grant application by the University of Melbourne to Sustainability Victoria.

During May and June 2023, CYP D&C, in collaboration with Rail Projects Victoria, has promoted the achievements of the research and field trials through a series of social media postings and industry newsletters, including RailExpress and CBD News, as well as being featured on the Victoria’s Big Build (Metro Tunnel Project) website. CYP D&C has also submitted the outcomes from the research and trials for the 2023 Premier’s Sustainability Awards (Victoria), as well as a conference paper submission for the 2023 National Transport Research Organisation (NTRO) International Technical Conference – Beyond Certainty (affiliated with Australian Road Research Board (ARRB)) in October 2023.

Describe WHO benefited from your initiative, innovation, or approach?

One of the key benefits of the initiative is identifying an emerging market for waste-based glass for Victoria and Australia.

The glass fines investigated in this research and trials have previously had limited end uses and are often stockpiled or sent to landfill. In 2019, the Parliamentary Budget Office found that an estimated 250,000 tonnes of glass waste was generated in Victoria annually, with only 40% being recycled. The remaining glass is overwhelmingly made up of glass fines that has to date been found to be inappropriate for recycling and therefore sent to landfill. These trials demonstrate the viability of adopting circular economy practices that create positive outcomes for the environment.

CYP D&C has engaged ecologiQ, the Victorian Government agency responsible for integrating circular economy objectives into Victoria’s transport infrastructure projects, to assist in our engagement with VicRoads and to utilise the knowledge gained to support a shift away from prescriptive-based specifications. Using the results of the research field tests to date, the project team can engage with stakeholders such as VicRoads and ecologiQ to consider reviewing concrete standards, which currently limit recycled content in aggregate to 30% (VicRoads Section 610). It is hoped through engagement with ecologiQ, and using the knowledge gained from trials undertaken on this project, that further opportunities will be identified on emerging major projects to continue field trials of this innovative research.

Excitingly, preliminary results from the research team indicate the glass could not only be used as a sand replacement, but that the finer grade of the glass sand has potential to act as a binder in the concrete, highlighting the opportunity for the glass fines to be used as a cement replacement and providing a significant impact on the decarbonisation of concrete. This represents a future trial opportunity at our surface works sites or on another project, pending further university research.

Additionally, the research team is investigating the possibility of upcycling other industrial by-products into concrete mixes in addition to kerbside glass. One of these focus items is solar photovoltaic (PV) panels – a growing waste issue – which are made from up to 80% glass. CYP D&C is hoping to support this research by trialling the PV mixes at future surface works sites during 2023 or 2024. Based on the outcomes of these trials, there is significant opportunity to benefit the solar PV industry and end-users.

What LEGACY and UN SDG CONTRIBUTION was achieved?

Climate Action; Responsible Consumption and Production

CYP D&C deliberately established sustainability objectives that require supply chain and research institution collaboration to urgently combat climate change and its impacts (UN Sustainable Development Goal (SDG) 13 ‘Climate Action’).

The study and associated trial of the recycled crushed glass concrete by CYP D&C at the Metro Tunnel Project’s La Trobe site has proven that glass sand can be used for large scale concrete production for structural concrete in building and infrastructure projects, while providing a reliable market for waste glass in Victoria and Australia, and reducing the reliance on natural or quarried sand for concrete production – aligning with UN SDG 12 ‘Responsible Consumption and Production’.

By providing a field trial site for the glass based concrete trials, CYP D&C is paving the way for the scaling up and full commercialisation of crushed waste-based glass as a sand replacement in the built environment. CYP D&C’s work has accelerated the potential uptake of recycled glass fines in the infrastructure and building industries, whilst demonstrating how circular solutions can be scaled across businesses, sectors, or whole systems.

The innovative research and process employed in this study has opened new areas of product development and demonstrated that recycled crushed glass is a viable sand replacement in structural concrete. With increased up-take by industry, the supply of glass sand is expected to improve and eventually become comparable to that of other raw ingredients of concrete. With recent investment in new glass crushing plants in Melbourne and surrounds, and Victoria’s Recycled First policy, the research is critical and timely. CYP D&C is proud to be undertaking these trials given the significant pipeline of concrete framed infrastructure and building projects in Victoria alone.

Partnerships, Collaboration and Innovation

The trials were successful due to significant partnerships and collaborative work between CYP D&C, research institutions and industry (UN SDG 17 ‘Partnerships for the Goals’). This study and subsequent trials open the door for industry to continue to develop this circular economy innovation.

The innovative research and field trials are in direct alignment with UN SDG 9 ‘Industry, Innovation and Infrastructure’. Through our collaboration with research and industry partners, CYP D&C is fostering innovative practices, and creating a roadmap for full-scale market transformation in circular economy of waste-based glass to be used in building and infrastructure projects.

The next steps, led by CYP D&C in collaboration with the University of Melbourne, are to increase knowledge about this innovative circular economy research and work with stakeholders and standards regulators in Victoria to accommodate higher percentages of recycled aggregate content in concrete standards.

The research and trials have the potential to leave a legacy on the construction industry to realise significant cost savings, diverting a significant amount of glass from landfill, and influence a uniform industry-wide specification change for the application of waste-based glass sand in concrete. It is hoped this study will challenge the current prescriptive-based specification approach for concrete in Australia – typically prohibiting innovation and the emergence of sustainable concrete technologies – and a move towards the application of performance-based concrete specifications in the built environment.